Precision Solutions, Expert Advice

Why Work With IPP?

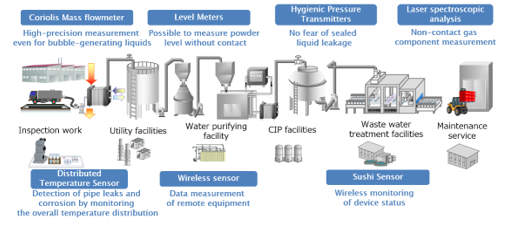

IPP Deliver some of the best specialist devices and tools on the market required in the highly regulated food & beverage industry. Paired with over 30 experience years in the food and beverage industry. Not only that, but with IPP you’ll have access to Brennan & Co’s comprehensive Service division, so your equipment will always be supported.

Applications/Success Stories

Maximising dryer performance in the dairy process

Using the NDC 710E Moisture Analysers, with near-infrared technology, IPP have assisted the Irish Dairy Industry in greatly improving their drying process on powder products.

pH reiner probe in aseptic design

The pH Reiner probe is used wherever increased demands are made on measuring accuracy, pressure, temperature, sterility and life cycle. For example, in flow fittings and reactors with high pressure, pressure pulses, or for inline cleaning.

pH Reiner Probe in Aseptic Design

Percent Concentration Measurement in Food Application

Percent concentration measurement in food application

This Application Note is designed to guide you through the programming steps required. All of the steps you will follow are in your ISC450 Instruction Manual, but we have pulled out just those steps that deal with setting up percent concentration using one of the “built-in” tables.

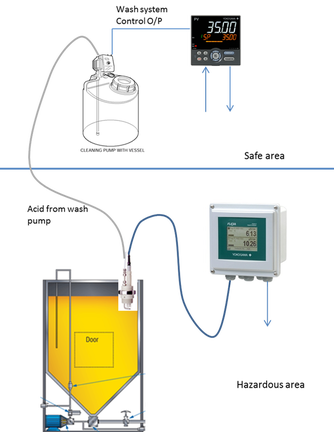

pH control and wash system for 2- wire transmitter using controller with PLC function

pH wash systems are a requirement for many industries where electrode fouling is common place. Large amounts of deposits form over a period of time preventing the sensors performing correctly. This results in measurement loss and repeated expensive electrode replacement. It is difficult to apply wash systems to 2 wire transmitters due to hazardous area restrictions therefore incorporating the wash function within a control device outside the hazardous area provides an cost effective solution.

By using the Yokogawa UT35A, it provides a cost effective solution for pH applications.