Is predictive maintenance on your radar?

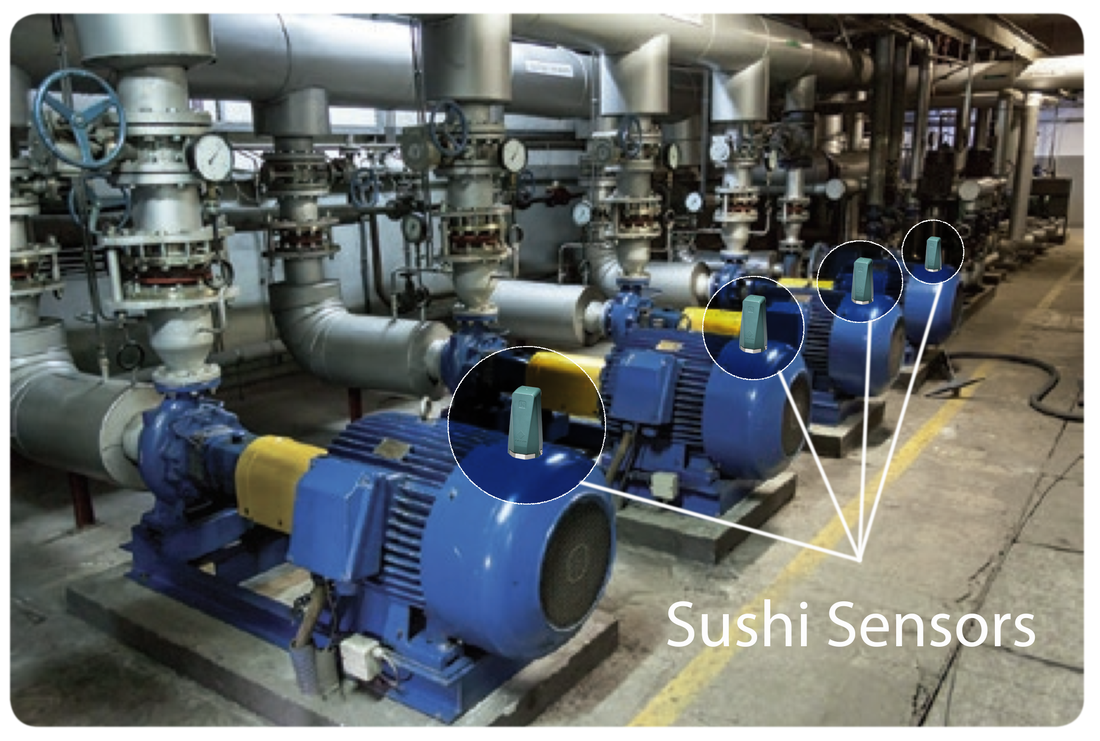

The Yokogawa Wireless Sushi Sensors won Plant Engineering’s ‘Product of the Year’ award to go with the PAM 2020 award for ‘Best Asset Monitoring Technology’.

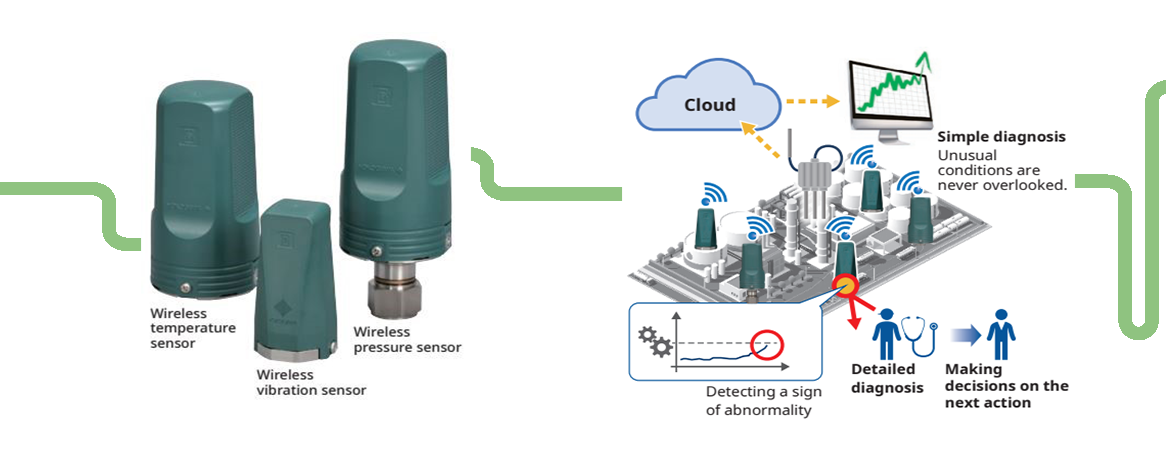

The Sushi Sensors utilise IIoT wireless technology to provide asset monitoring of critical equipment for preventative maintenance.

Parameters monitored include Vibration, Pressure and Temperature.

These products can prevent costly downtime and equipment repairs while improving safety for process equipment and plant personnel.

Speak to Ryan our Product Specialist

Request a CALL BACK or QUOTATION

Yokogawas’s ideal equipment maintenance

To ensure the safety and quality of production, it is important to maintain production equipment appropriately. Sushi Sensor can help perform the following tasks for condition-based maintenance (CBM):